sustainable, efficient, scaleable

reTyre Smart Manufacturing

At reTyre, we’ve compressed traditional tyre manufacturing—once reliant on massive facilities, outdated processes, and resource-heavy methods—into a smart, automated system powered by advanced technology. By doing so, we’ve achieved unmatched levels of sustainability, efficiency, and scalability

Conventional Manufacturing vs. reTyre

For decades, tyre manufacturing has remained largely unchanged, relying on rigid, resource-heavy processes such as vulcanising, sprawling assembly lines, and outdated machinery. These entrenched methods have prioritised high-volume, standardised production at the expense of innovation, sustainability, and flexibility. As global demands shift toward greener and more efficient solutions, traditional processes have proven incapable—or extremely difficult—of adapting, slowing the progress of sustainability in the tyre industry.

At reTyre, we’ve broken free from these limitations by adopting innovative, smart, and automated manufacturing processes that address the inefficiencies and environmental challenges. Here’s how reTyre stands apart:

| Aspect | Conventional Manufacturing | reTyre Manufacturing |

| Production Process | Manual vulcanizing | Automated injection moulding |

| Production Model | Mass production with high volumes and little variation | Automated production, increasing efficiency and scalability |

| Machinery | Complex, outdated machinery requiring large assembly lines | Smart, automated manufacturing with efficient micro-factories |

| Flexibility | Limited: Difficult to adapt to changing demands | High: On-demand manufacturing tailored to market needs |

| Materials | Predominantly rubber, reliant on carbon black and vulcanization | Diverse material options, unlocking innovations |

| Sustainability | Limited – Reliant on traditional materials and processes | High – Eco-friendly materials and sustainable production methods |

| Environmental Impact | High – Due to lack of recycling abilities, deforestation, production inefficiencies, and centralized facilities | Low – Minimized waste, energy-efficient processes, and reduced carbon footprint |

| Innovation Speed | Slow – Long lead times for design and delivery | Fast – Agile development cycle for rapid improvements |

re

SMART MANUFACTURING HUBS

Unique Supply Chain Benefits

Our processes demand significantly less space, energy, water, and manpower, paving the way for sustainable manufacturing facilities across multiple continents.

Key Benefits

- Network of Manufacturing Hubs:

Global reach with local efficiency. - Seamless Supply Chain Integration:

Smooth operations from production to delivery. - Risk Reduction:

Minimized operational disruptions. - Operational Continuity:

Consistent and reliable production. - Sustainability:

Reduced emissions and waste through localised production. - Efficient Tyre Access:

Improved distribution channels and short delivery routes. - Swift Response:

Quick adaptation to market and production demands.

Made in

A new era

Smart Manufacturing – What Does It Actually Mean?

Beyond our proprietary manufacturing process and ability to use innovative bio-materials, reTyre’s approach leverages smart technologies that transform the production process:

Low Risk:

- Advanced technologies like smart sensors and predictive analytics prevent issues before they occur.

- Proactive maintenance ensures consistently high quality and minimises operational risks.

Real-Time Inventory Insights:

- reTyre provides unparalleled access to tyres through real-time inventory tracking.

- This enables just-in-time production, reducing waste and optimising inventory management.

Swift Changes:

- Data analytics and machine learning empower rapid responses to market demands.

- This agility fosters efficient production and keeps us ahead of industry trends.

Experience smarter, greener, and more adaptable tyre manufacturing with reTyre – built for today and ready for tomorrow.

Are you interested in investment opportunities?

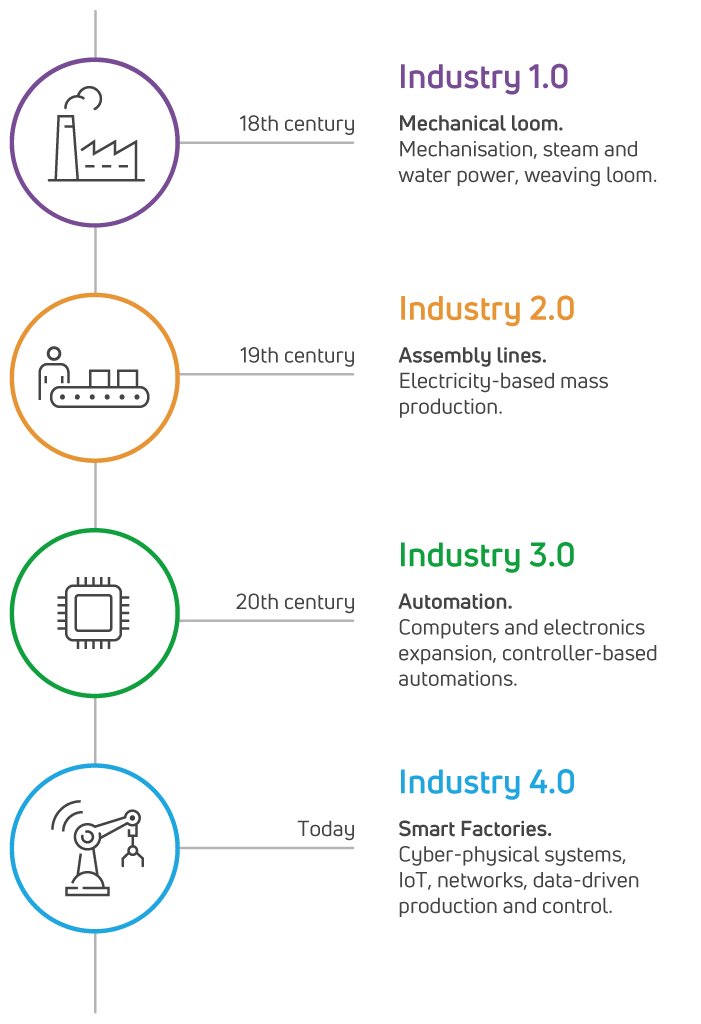

Industrial revolution

Setting New Standards For The Industry

In Industry 4.0, manufacturing evolves with seamless supply chain integration, enhancing communication and efficiency. Real-time connectivity streamlines processes, minimizing lead times and improving overall effectiveness.

This work is licensed under CC BY-ND 4.0

Industry 4.0 enables remote monitoring and management, ensuring operational continuity and efficiency, which are vital for industries with continuous production cycles.

You are interested and want to get an introduction?